A Slasher

is not just

a Slasher

“Since purchasing a Woods slasher we do not need to use our mulcher.

A woods slasher does not leave a windrow, distributes material evenly and allows us to work faster than when we were using mulchers.

The lower operating costs and the ease of operation for both the tractor and operator make the decision to purchase a Woods slasher an easy one.”

Geoff & Andrew

Graziers, Feedlotters & Woods Owners

Know Your Why?

| Mulcher | Slasher | |

|---|---|---|

| Doesn't leave a windrow? | ||

| Want grass chopped into a fine finish? | ||

| Want to cut large volumes with minimal HP? | ||

| Want to reduce running costs? |

What to Maintain?

| Mulcher | Slasher | |

|---|---|---|

| Gearbox | ||

| PTO Shaft | ||

| Blades | x2 | |

| Belt |

So... Why Woods?

| Woods Exclusive Features | Woods Exclusive Benefits |

|---|---|

| Made in USA with American steel | Quality inputs, quality product, designed and manufactured to last |

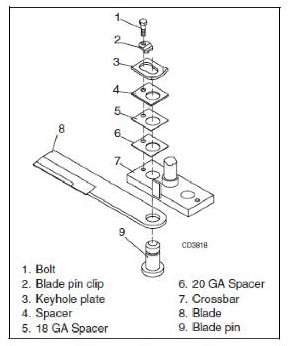

| Change blades from above slasher | Highest OH&S rated slashers - greater value for money and reduced risk assessments |

| Quick Change Blades System | Change blade within minutes and reduce the cost of downtime. Change blades roadside with light hand tools |

| 4x stronger blade pin 38mm (1.5”) compared to 19mm (3/4”) bolt on other slashers | Thinner bolts will wear quickly increasing chances of throwing a blade |

| Greaseable blade pin | Ensure long life out of blade set reducing running costs |

| Built on complete subframe | Increased structural integrity - stress points on frame not on skin. Optimal for efficient cut |

| Stump jumping disc | Blades do a full 360° rotation minimising impact and protecting gearbox when slashing |

| Does not leave a windrow | Efficient distribution of material, reduced risk of personnel and machinery |

| 10 year gearbox warranty | Confidence in design and function of gearbox for reliable slasher |

woods exclusive quick change blade pin system

superior design, durability and style under the deck, too!

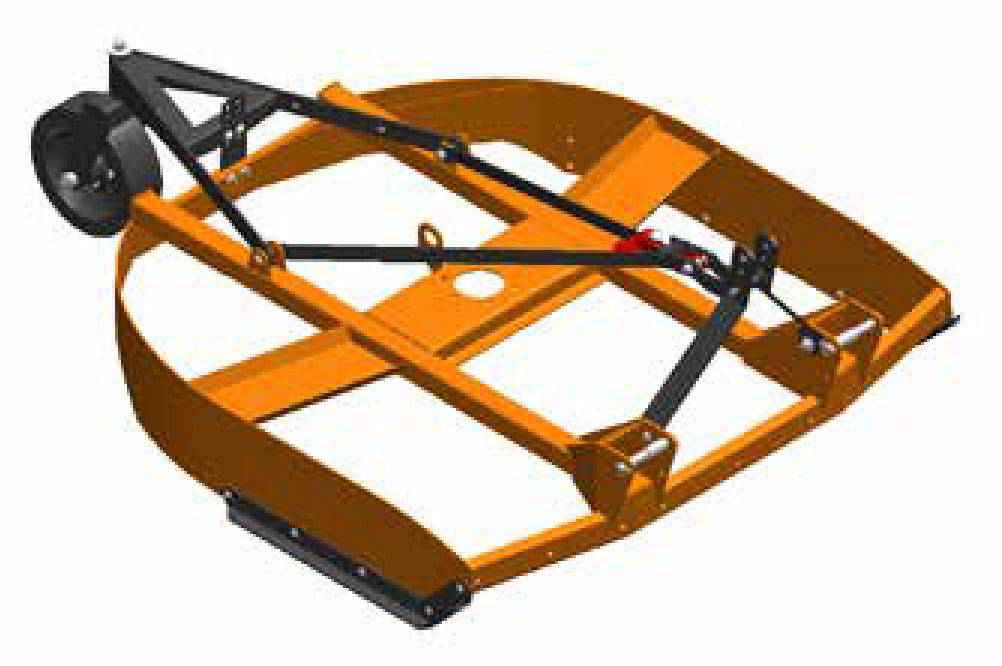

bb72.50 brushbull frame

SAFETY FIRST

OH&S Features unique to Woods slashers

- Change blades from above the machine: no risk to operators or maintenance crews of having to get under slasher to change the blades. Slasher does not need to be on stands.

- Quick Change Blade System removes labour and material to change blades: only light hand tools required to change blades. No oxy or grinding risk.

- Will not leave a windrow: superior material discharge management as material will be spread evenly across the back of the slasher limiting risk to plant and personnel.

- 38mm blade pin: is 4x stronger than the standard 3/4” bolt on standard slasher. A 3/4” bolt is more likely to wear through and throw blades.

- Tip Speed is not excessive: Woods tip speed is efficient for design of slasher. Excessive tip speed is not tolerant to hitting objects increasing chances of breaking/throwing blades.

A SLASHER is not just a slasher

EFFICIENCY

Operating and R&M Cost Efficiency

- Full structural sub frame increases integrity of slasher making it more durable than other slashers and fitting for our Australian conditions.

- Machined gearbox hubs and tight tolerance steel shield will prevent any material affecting lower gearbox seal ensuring long life out of gearbox with no oil leaks.

- Driveline hanger will prevent dirt and water affecting shaft when removed from tractor.

- 38mm blade pin is 4x stronger than standard blade bolt so is slower wearing than others.

- Quick change blade pin system allows operators to change blades within 5 minutes with light hand tools. Can be completed roadside reducing downtime of machines.

- Greaseable blade pins ensure long life of blades and pins lowering R&M costs.

- Stump jumper allows for less shocks to gearbox and blades can spin 360° upon impact compare to a beam where large shocks emitted to gearbox and blades can become wedged in beam.

- Large deck clearance allows for large volume of material to be cut without choking and uses less HP and fuel.

Check out the range

Batwing Series

Woods Batwing™ Flex Wing Slashers are the only true Batwing™ in the Australian market.

Available in 12ft, 15ft or 20ft models in standard duty and heavy, extra heavy and extreme heavy-duty options.

The Woods Batwing™ is the heaviest built flex wing slasher in the Australian market and will cut material up to 115mm in diameter.™

Brushbull Series

Woods Single Spindle Slashers range from 5ft to 7ft cut in various series ranging from standard duty with a cutting capacity of material with a 50mm diameter to extra heavy duty with a cutting capacity of material with a 100mm diameter.

Dual Spingle Series

The Dual-Spindle series of Woods slashers come in various options including normal or offset trailing capacities.

There are also drawbar or linkage options on all models.

RC Series

The RC series is the lightest duty slasher series produced by Woods.

This series is designed for compact and sub-compact tractors with a tractor horsepower ranging between 15hp and 60hp.

This series will cut up to 25mm thick material and has a 60hp gearbox.